AT FLAIR, SERVICE IS KEY.

We are there for our optical retail partners. FLAIR offers services such as temple extensions, repairs and much more.

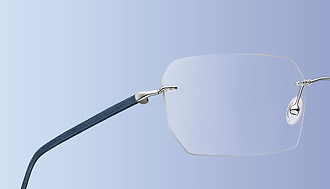

IMPLEMENTATION OF PURE TECHNOLOGY

Here you can find details, step-by-step manuals

as well as helpful expert hints and tricks for a perfectly executed glazing.

Your benefits with the FLAIR world patent:

-

Highest flexibility

-

Minimum risk of lens breakage

-

Maximum field of vision

-

Screwless and maintenance-free

-

Ultralight wearing comfort

Your benefits with the FLAIR world patent:

With our detailed step-by-step instructions and expert tips and tricks, you can easily glaze FLAIR glasses yourself. You can find all the steps for perfect glazing here:

Unsere neuen Verglasungs-Flatrates im Überblick

PURE TECHNOLOGY 3

2 holes

VERY IMPORTANT:

1) 1,0 mm drill

2) 1,5 mm ball-head drill

3) 60° countersink

4) Special FLAIR Nylon

6) 1,8 mm minimal edge thickness

Size

M

Height

169

Bust

102

Waist

90

Length

163

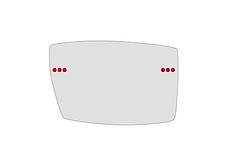

PURE TECHNOLOGY

3 holes

VERY IMPORTANT:

1) 0,9 mm drill

2) 1,4 mm ball-head drill

3) 60° countersink

4) Special FLAIR Nylon

5) All holes 0.9 mm. Never bigger!

6) 1,8 mm minimal edge thickness

You can download all further information regarding glazing, i.e. drilling coordinates, here:

The PURE has 3 holes on each side, the PURE3 only 2 holes. Thus, the PURE3 offers 30% more field of vision than the PURE and about 20% more than with conventional plug or screw systems.

Important: the hole size also differs – this is very important. At PURE the holes have a diameter of 0.9 mm and at PURE3 it is 1. 0 mm.

Therefore, it is imperative to use the right tools and drills.

Precision is absolutely key. Drill the holes with the right tools in the exact size and positioning. You cannot make up for an inaccurate hole.

Be also sure to use the special FLAIR nylon thread. Art.-No. 326 069. It has a special structure, flexibility and UV resistance. Do not use any other nylon threads.

Deburr all holes with our matching ball head countersink. Inside and outside. And properly (until the ball head disappears completely) countersink the hole in which the knot will disappear later.

Make sure that the edge / lug is positioned exactly on the edge of the lens later on. If the lens thickness is very thin, slit the glass slightly and move the holes inwards accordingly.

When putting in the thread, make sure to pull it really tightly.

Also note that the position of the nylon on the bridge and edge / lug slightly differ from each other.

See all the steps and a few more expert tips in our new PURE3 animation video. Or contact our in-house glazing service.

Make sure to imperatively use the following tools:

Special FLAIR nylon thread (Art.-No. 326 029)

A 1.0 mm drill for the PURE3 (2-hole) and a 0.9 mm drill for the PURE (3-hole)

A 1.5 mm ball head lowerer (Art.-No. 60 087)

Precision pliers for cutting the threads. (e.g. Art.-No. 60 019)

Two flat pliers, as mostly available in any workshop

All tools are also available from our customer service and the FLAIR webshop: www.flair.de/shop

Yes. The PURE3 (2-hole) must be drilled with a 1.0 mm hole (and corresponding drill) and the PURE (3-hole) must be drilled with a 0.9 mm hole. Apart from that, you can use the same tools.

The tools are also available in our webshop: www.flair.de/shop

Yes. There are glazing instructions, step-by-step instructions, and videos for both technologies.

You can find them here. In addition, appropriate glazing instructions are included in the case of each FLAIR frame.

For more information about the glazing, please contact our glazing service or our special customer service in Oelde.

verglasungsservice@flair.de | +49 2521 8400-22

export@flair.de | +49 2521 8400-59

(Please ask for our technical specialists.)

Yes. At FLAIR we operate an in-house glazing lab.

You can reach it at:

verglasungsservice@flair.de | +49 2521 8400-22

For some direct markets we also offer great flat rate tariffs for unlimited all-round carefree glazing. More information about the glazing service with your representative or distributor.

Yes. We offer drilling coordinates for the Less Stress, CNC machines or any other automatic grinding machine. For the latter, please use the txt-oma-vca templates, which you can convert to the appropriate format for your own specific machine.

You can find the data here.

With the PURE as well as PURE3, precision is very important.

Therefore, we definitely recommend the use an automat or CNC.

You can also use a Less Stress.

If you use a classic hand drill, please make sure to use our drilling templates. Available from customer service or in the webshop at: www.flair.de/shop

Very important: all drill holes must be precise. In addition, the nylon thread (only use the special FLAIR nylon thread!) must always be tightened as strongly as possible. Ideally, move the nylon very close to the edge of the lens before knotting the thread. On the bridge as well as especially on the edge / lug. If necessary, also help with your finger(nail). Then imperatively tighten really strongly. Make sure to use two flat pliers. Only then do the final knot. You can see how it all looks in our glazing instructions or in the detailed step-by-step animation video. Once tightly knotted, the thread does not get loose or lever up and gives you maximum maintenance freedom.

No. Basically, PURE TECHNOLOGY is probably the most flexible technology with the widest possibilities in for rimless eyewear. However, we recommend a minimum lens thickness of 1.8 mm. For very thin lenses, we advise to slightly slit the glass sideways (and move the holes inwards accordingly). The strength of PURE TECHNOLOGY is its flexibility. However, if you prefer it a bit more firm, you can also choose this option.

To remove the demo lenses, always cut the nylon threads on the (inner) side facing the eyes with the precision pliers and loosen the thread with targeted lever movements. This will prevent you from damaging the material / colouring.

All parts / pin fittings must always be adapted to the curve of the lens and lie as flat as possible on the lens. By slightly "tilting" the pin, an optimal support needs to be created. The fitting of the parts / pins can be different if the glass curves have different radius on the right and left.

Apart from that, the nylon thread position differs minimally between the edge / lug and the bridge. For details, see our glazing instructions or our animation videos.

A major strength of PURE TECHNOLOGY is its maximum freedom of maintenance. Once properly glazed, the nylon thread does not loosen or lever up as with other technologies. When glazing for the first time, it is important to adjust the nylon thread correctly before tightening and knotting and to put it under maximum / shortest tension. If necessary, also use your finger(nail) to push it into the optimal position and tighten it properly.

Details and step-by-step instructions can be found in our glazing instructions or our animation videos.

No. Under no circumstance. Please imperatively always use the original special FLAIR nylon thread. This is particularly stretchy, UV-resistant and has a special surface structure. This means that it only needs to be knotted once with a simple knot and will not come loose again.

The glazing instructions as well as step-by-step animation videos can be found both here in the Glazing & Service section and for download here in the Technical Data & Downloads section.

All the necessary tools can be found in the FLAIR webshop: www.flair.de/shop.

Basically not necessary. Except if the minimum edge thickness of 1.8 mm is not reached or in case of high glass thicknesses. Particularly with very thin lenses, slitting / notching can provide increased stability and rigidity.

Basically, PURE TECHNOLOGY is the lowest-risk and most maintenance-free technology on the market. The special permanently elastic FLAIR nylon thread absorbs a lot of tension and reduces the risk of lens breakage to a minimum.

Nevertheless: in general, but especially for thin lenses, it is always recommended to choose lenses with a refractive index of 1.6 or 1.67 for glazing.

No. The PURE3 is the evolution of our long-proven and globally popular world patent. With a little practice, it is just as easy to glaze as the PURE and also just as fast in terms of speed as the PURE or other technologies.

Our in-house glazing service is also available to answer any questions, provide training, etc. You can reach them at verglasungsservice@flair.de | +49 2521 8400-22 or via our FLAIR customer service, where they will be happy to connect you on: export@flair.de | +49 2521 8400-59.

We currently offer larger group glazing seminars mainly on demand. In addition, our in-house glazing service is always available for online or telephone service after consultation.

You can reach us via mail or phone at verglasungsservice@flair.de | +49 2521 8400-22.

The general terms and conditions of our service lab (glazing service) can be found here:

FLAIR on Instagram

Home